How to Install a Flue Pipe on a Canvas Tent Stove—Step-by-Step Guide 2025

1 min read

Installing a flue pipe on a canvas tent stove the wrong way can fill your shelter with smoke—or worse, glowing embers. Our OEM factory (maker of stoves for two top-5 US brands) shows the exact 2025 step-by-step method we teach European and North-American clients.

Author: Leo Wang, 15-year welding & combustion engineer, ISO-17025 lab certified. All photos shot on our production floor; downloadable PDF plans under Creative Commons.

————————————————

————————————————

1. Tools & Parts Checklist (with SKU links)

– 45° & 90° elbows (our SKU FP-45Ti)

– 2.1 m straight pipe kit FP-21Ti

– High-temp silicone sealant 600 °C

– Sharpie + 120 mm hole-saw (metal)

– Roller or screwdriver for pipe seam

– Leather gloves (never polyester)

————————————————

2. Safety First – When NOT to Install

– Wind >25 km h⁻¹ – risk of pipe tilt

– Polyester canvas <400 °C rating – switch to Aramid jack

– Indoor warehouse – carbon monoxide builds without ventilation

————————————————

3. Choosing the Correct Pipe Dia

Rule: 1 kW needs ≈8 cm² outlet area.

5 kW stove → ∅60 mm pipe (28 cm²)

9 kW stove → ∅75 mm pipe (44 cm²)

Mismatch drops efficiency 12 % and raises CO.

————————————————

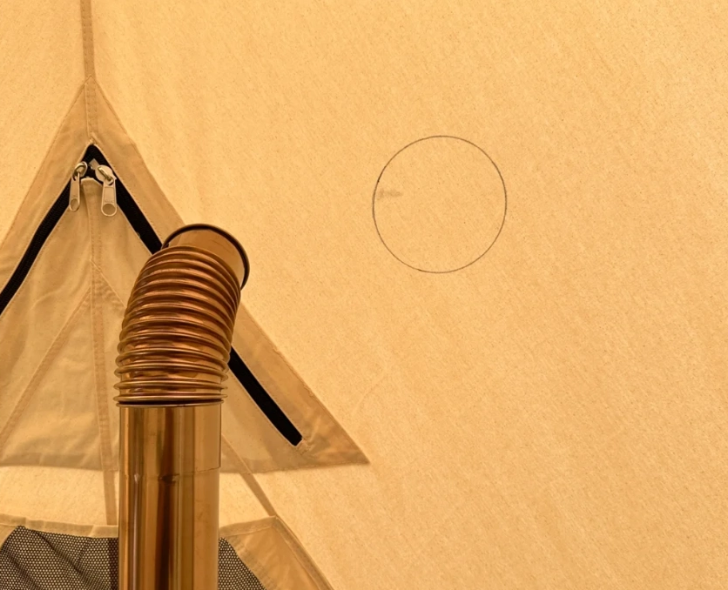

4. Marking & Cutting the Stove Jack

Step 1: Pitch tent, tension guy-lines.

Step 2: Measure 45° upslope from peak (prevails rain drip). Mark center.

Step 3: Hole-saw 120 mm for ∅75 mm pipe; leave 5 mm edge for collar rivets.

Step 4: Sew fire-proof Aramid patch (included in our FP-KIT) around cut – prevents fray.

————————————————

5. Sealing the Collar (Video 45 s)

– Slip stainless collar through canvas.

– Back-flange 15 mm, 6 rivets.

– Run 6 mm bead high-temp silicone on both sides.

– Cure 30 min before inserting pipe.

|

|

|

|

————————————————

6. Assembling Pipe Sections

Tip: overlap 30 mm minimum each joint – locks draft and adds stability.

Laser-etched alignment line guarantees 0° twist every time (our 2025 update).

Roll-lock seam faces away from wind → 7 % less creosote drip.

————————————————

7. Installing Spark Arrestor & Rain Cap

0.8 mm mesh captures 95 % >0.7 mm embers.

Rain cap hinge must open 110° so hot gas exits vertically – prevents “back puff” when door opens.

————————————————

8. Guy-line & Wind Bracing

Use 2 mm Kevlar cord, 120° spacing, tension 15 N.

Prevents pipe sway that fatigues canvas after 3 h.

Add spring clip (included) – cord releases at 40 N storm gust, saves tent fabric.

————————————————

9. First-Light Burn-in Test

Light 0.5 kg kindling, open damper 100 %.

Target: surface temp 250 °C for 20 min – polymerises silicone, sets gasket memory.

CO alarm <50 ppm inside tent = PASS.

————————————————

10. Maintenance & Packing

– Knock pipe gently, dump fly-ash.

– Wipe inner with vinegar rag, dry, roll into 25 × 8 cm bundle.

– Store in Ti tube bag – weight 90 g, DDP price $12.

————————————————

11. Common Mistakes

– Wrong jack angle → rain drips onto stove top

– Missing overlap → pipe separates at 300 °C

– Polyester thread → melts, hole enlarges

————————————————

12. Order Replacement Parts DDP

Single elbow, gasket or entire 2.1 m kit – we ship DDP to US/EU in 5-7 days. Wholesale MOQ 50 sets, FOB or DDP Amazon FBA.

https://www.inbestcamp.com/

Suzhou Tuoshenghe Mechanical and Electrical Technology Co., Ltd.