Lipstick labeling machine: efficient labeling, helping to create exquisite packaging

4 min readIn today's fiercely competitive cosmetics market, packaging has evolved beyond simply protecting the product; it has become a crucial component of brand image and market competitiveness. Lipstick, a star product in the female consumer market, demands exceptional design and packaging craftsmanship. The emergence of lipstick labeling machines in the lipstick packaging process provides companies with an efficient, precise, and aesthetically pleasing labeling solution, making them an indispensable piece of cosmetics labeling equipment in automated production lines.

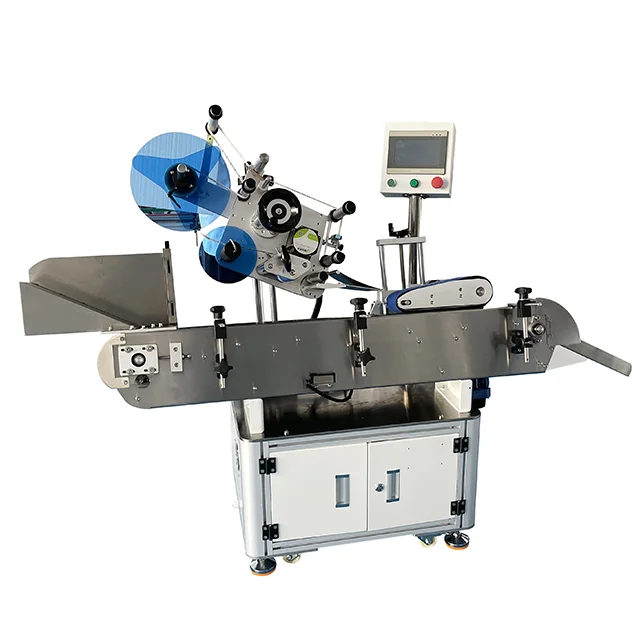

1. What is a lipstick labeling machine?

A lipstick labeling machine is an automated labeling system specifically designed for cylindrical or irregularly shaped cosmetic products such as lipstick and lip gloss. Compared to traditional manual labeling methods, it achieves precise positioning, secure application, and efficient label delivery on high-speed production lines.

Key functions include:

Automatic conveying: Lipstick products are fed into the labeling station in an orderly manner.

Precise positioning: Sensors and control systems identify product position to ensure accurate label application.

High-speed labeling: High-volume labeling can be completed in a short time.

Intelligent detection: Features such as missing and duplicate label detection ensure consistent product quality. Essentially, a lipstick labeling machine is more than just a piece of equipment; it's a crucial component in achieving intelligent manufacturing for modern cosmetics companies.

2. Advantages of Lipstick Labeling Machines

Improving Production Efficiency: Manual labeling is often inefficient and unstable, while lipstick labeling machines can complete labeling at a rate of dozens to hundreds of units per minute, significantly increasing production capacity and meeting peak season order demand.

Ensuring Labeling Accuracy: Consumers are particularly concerned about the aesthetics of lipstick packaging when purchasing it. Labels with skew, bubbles, or warped edges can directly impact the purchasing experience. Lipstick labeling machines utilize photoelectric detection and positioning systems to minimize errors, ensuring neat and beautiful labels.

Reducing Labor Costs: With rising labor costs, the use of automated equipment can significantly reduce manual labor. Labeling tasks that previously required multiple people can now be completed by a small number of personnel, requiring only a small number of operators and supervisors.

Enhancing Brand Image: Exquisite packaging can make a product stand out on the shelf, and the high precision and consistency of lipstick labeling machines ensure that each lipstick presents a consistent and professional brand image. Compliance and Traceability: The cosmetics industry has strict requirements for product traceability and label compliance. Lipstick labeling machines can be integrated with printing systems to simultaneously print information such as batch numbers and anti-counterfeiting codes while applying labels, facilitating traceability management.

3. Application Scenarios for Lipstick Labeling Machines

Fully automatic lipstick labeling machines are widely used in the cosmetics industry, including:

Cylindrical lipsticks and lip glosses;

Square lipsticks;

Small-sized products such as lip balms and color-changing lipsticks;

Other cylindrical cosmetics such as eyeshadow sticks, mascara, and concealer sticks.

For small and medium-sized businesses, semi-automatic lipstick labeling machines can also meet production needs with lower investment costs. Some multi-functional machines also support bottle labeling, offering greater flexibility.

4. How to Choose the Right Lipstick Labeling Machine

When purchasing lipstick labeling machines, consider the following key points:

Capacity and speed: High-volume factories are more suitable for fully automatic, high-speed lipstick labeling machines, while small cosmetics contract manufacturers can opt for semi-automatic equipment. Labeling Accuracy: High-end brands should choose high-precision servo-driven lipstick labeling machines to ensure consistent label placement.

Adaptability and Flexibility: High-quality equipment supports quick switching between different specifications, meeting the needs of labeling multiple lipstick sizes.

Ease of Operation and Maintenance: Easy-to-operate lipstick labeling machines can reduce employee training costs and improve production continuity.

After-Sales Service and Stability: High-quality lipstick labeling machine manufacturers not only provide the equipment but also provide long-term technical support and maintenance guarantees.

5. Lipstick Labeling Machine Maintenance and Care

Regular Cleaning: Keep the conveyor belt, labeling head, and sensor clean to prevent dust and glue residue from affecting labeling results.

Lubrication and Maintenance: Regularly lubricate transmission components and bearings to reduce wear.

Consumables Inspection: Promptly replace aging or damaged consumables such as label paper and rubber rollers.

Software Upgrade: Update the control system software according to the manufacturer's instructions to ensure optimal equipment performance.

Personnel Training: Operators should receive regular training to ensure proper operation and maintenance of the equipment. For cosmetics companies, lipstick packaging is not only about aesthetics but also reflects brand competitiveness. Lipstick labeling machines, with their high efficiency, precision, and intelligent features, are becoming a crucial tool for companies to upgrade their packaging. Whether fully automatic or semi-automatic, the proper selection and application of these machines can help companies achieve both efficient production and beautiful packaging.

With the continued advancement of automation and intelligent manufacturing, lipstick labeling machines will continue to innovate, helping cosmetics companies stand out in the fiercely competitive market.

Beilt specializes in selling a wide range of labeling machines, including lipstick labelers, round bottle labelers, flat labelers, and fully automated labeling lines. These are widely used in the cosmetics, food, daily chemical, and pharmaceutical industries. Leveraging extensive industry experience and comprehensive after-sales service, Beilt not only provides customers with efficient, precise, and stable labeling equipment, but also offers customized solutions tailored to the production needs of individual companies, helping them improve production efficiency and packaging quality.

www.beiltpack.com

beiltpack