Maintenance Tips for Five-Axis Gantry Cranes: Ensuring Longevity and Performance

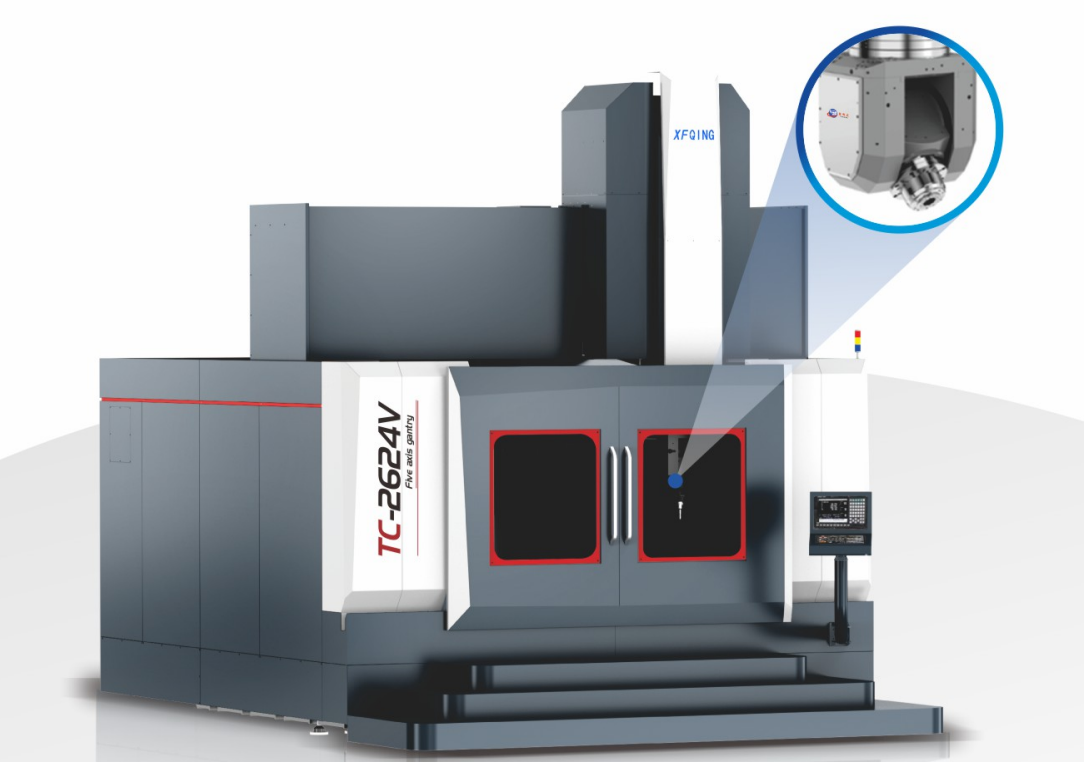

4 min readIn modern industrial and precision machining environments, five-axis gantry cranes have become indispensable for their ability to maneuver heavy components with exceptional accuracy and flexibility. These advanced systems are especially critical in industries that demand high-precision equipment, such as aerospace, automotive, mold manufacturing, and heavy-duty machining.

As a company committed to quality and innovation, Zhiquan—a leading manufacturer of CNC machining centers, wire-cut EDM, electrical discharge machines, and milling machines—recognizes the importance of keeping all machinery, including auxiliary systems like gantry cranes, in peak condition.

In this article, we share practical maintenance tips for five-axis gantry cranes to ensure their longevity, safety, and optimal performance.

1. Establish a Routine Inspection Schedule

Consistent maintenance begins with regular inspections. Create a daily, weekly, and monthly checklist to monitor components such as:

Cable integrity and alignment

Limit switches and control systems

Gearbox lubrication levels

Hoist operation and chain condition

Beam and rail wear or misalignment

Daily visual checks can catch early signs of wear, while monthly inspections should involve more detailed diagnostics. At Zhiquan, we recommend integrating crane checks into your broader equipment maintenance program to prevent unexpected downtime.

2. Monitor and Maintain the Electrical System

Five-axis gantry cranes rely on complex electrical controls and servo systems. Poor electrical maintenance can lead to system failures or erratic crane behavior.

Key tips:

Inspect wiring for fraying or loose connections

Check grounding systems to prevent surges

Test emergency stops and limit switches regularly

Ensure control panels are free of dust and moisture

Since Zhiquan’s CNC machining centers and EDM machines operate in precision environments, it’s crucial that your crane’s control systems match the same level of reliability.

3. Lubricate Moving Parts Consistently

Proper lubrication minimizes friction and wear, especially in rails, bearings, gearboxes, and chains. Each component has its own lubrication schedule and recommended grease or oil.

Use manufacturer-recommended lubricants

Clean surfaces before reapplying grease

Avoid over-lubrication, which can attract dust and debris

Crane components should be lubricated as often as every 100 operating hours, depending on usage intensity. Zhiquan’s precision machines benefit from this maintenance by ensuring material handling is smooth and shock-free.

4. Align and Calibrate Axes

Five-axis systems demand precise axis synchronization to maintain balance and accurate positioning. Misalignment can lead to:

Increased mechanical wear

Stress on servo motors and guide rails

Inefficiencies in material loading and unloading

Use laser alignment tools or digital indicators to check that all axes move smoothly within designated tolerances. This is particularly critical when feeding material into Zhiquan’s CNC centers or wire-cut EDM systems, where micrometer precision is essential.

5. Keep Rails and Work Areas Clean

Dust and debris buildup can interfere with crane mobility and cause scoring on rails and wheels. Always:

Sweep and clean gantry paths daily

Use protective covers when the crane is not in use

Avoid leaving metal chips or coolant residue near the base of the crane

In machining environments where milling and EDM are ongoing, cleanliness is key—not only for crane function but for maintaining the integrity of your entire production line.

6. Train Operators and Document Maintenance

Even the best-maintained crane can be compromised by poor operation. Proper training ensures:

Safe and efficient handling of loads

Understanding of load limits and crane behavior

Immediate reporting of anomalies

Maintain a logbook or digital record for all inspections, maintenance actions, and repairs. This documentation helps identify recurring issues and supports preventive maintenance strategies.

At Zhiquan, we emphasize operator training not only for our high-precision machining tools but for all support systems in the workshop.

7. Schedule Professional Servicing

While in-house maintenance is vital, it’s equally important to schedule annual or biannual professional servicing. Certified technicians can:

Perform in-depth diagnostic checks

Replace worn-out components

Upgrade control software or firmware

Calibrate sensors and feedback systems

Zhiquan often collaborates with crane and automation specialists to ensure all systems supporting our CNC machinery run at their full potential.

Conclusion

Maintaining a five-axis gantry crane isn’t just about prolonging its lifespan—it’s about protecting the productivity and safety of your entire machining environment. Whether you're operating a heavy-duty CNC center, a high-precision EDM machine, or a robust milling setup, your crane must function as reliably as the equipment it supports.

Zhiquan is proud to provide cutting-edge CNC machining centers, wire-cut EDMs, and milling machines, and we believe that proper maintenance of all supporting systems—including gantry cranes—is essential for performance excellence.

Understanding the Role of Five-Axis Crane Gantries in Smart Factories

www.szzhiquan.com

Suzhou Zhiquan Electromechanical Equipment Co., Ltd.