Reducing Maintenance Costs with Durable Telescopic Chute Hydraulic Systems

4 min readIn heavy-duty industries such as mining, construction, agriculture, and material handling, telescopic chute hydraulic systems are essential components for efficiently transferring bulk materials. Their performance directly influences operational costs, maintenance frequency, and workplace safety. Choosing a durable and intelligently designed hydraulic chute can significantly reduce downtime, repair expenses, and energy consumption.

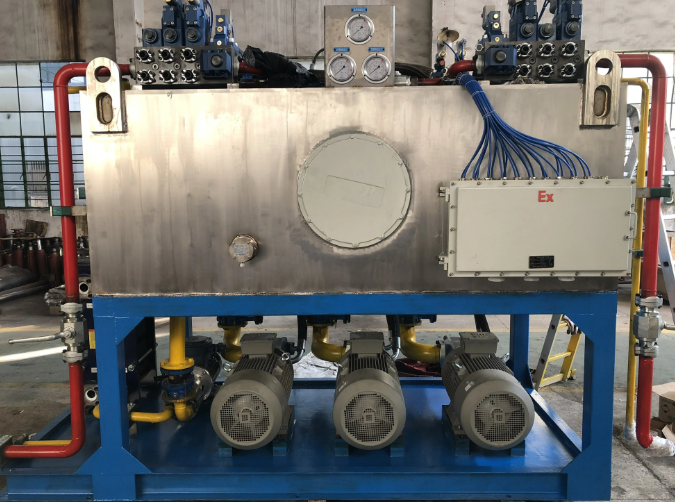

Huoheshi Hydraulic, a leading high-tech hydraulic supplier, leverages decades of experience, advanced engineering software (CAXA, CATIA, FLUIDSIM), automated manufacturing, and lean Six Sigma management to deliver cost-effective, safe, and high-performance telescopic chute systems. This article provides an in-depth analysis of how Huoheshi’s solutions reduce maintenance costs while optimizing industrial workflows.

1. Structural Anatomy: From Core to Exterior

Understanding the inner mechanics and external design is key to analyzing maintenance costs.

1.1 Hydraulic Core System

-

Multi-stage hydraulic cylinders provide smooth, controlled extension and retraction.

-

Variable displacement or load-sensing pumps adjust flow to match load requirements, reducing energy waste.

-

Key valves like proportional and counterbalance valves prevent sudden chute drops and shocks, protecting components.

1.2 Chute Body Design

-

Made from high-strength steel (Q690) and wear-resistant NM400 linings, offering long-term durability.

-

Anti-abrasion coatings and surface treatments minimize friction and material wear.

-

Modular design allows easy replacement of wear-prone sections, further reducing maintenance frequency.

1.3 Sensors and Control Systems

-

Integrated displacement sensors and encoders deliver millimeter-level positioning accuracy.

-

PLC-based control supports manual, semi-automatic, and fully automated operation, improving loading precision and reducing human error.

1.4 Safety Integration

-

Overload protection valves prevent hydraulic failure.

-

Collision detection sensors protect both the chute and the vehicle.

-

Emergency manual pumps allow safe operation during power outages.

2. Operational Principles and Performance Optimization

2.1 Smooth Material Flow

-

Telescopic chutes regulate extension speed to prevent spillage, reducing material loss and cleanup costs.

-

Hydraulic damping minimizes vibration and impact on structural components.

2.2 Energy Efficiency

-

Intelligent pumps and pressure regulation reduce unnecessary energy consumption, lowering operational costs.

-

Load-adaptive flow systems extend component lifespan by avoiding hydraulic stress.

2.3 Maintenance-Friendly Design

-

Modular, easily accessible components simplify routine inspections and part replacements.

-

Sensors provide real-time monitoring for predictive maintenance, enabling early detection of leaks or wear.

3. Applications Across Industries

| Industry | Typical Use Case | Maintenance Impact |

|---|---|---|

| Mining | Coal or ore transfer to trucks or trains | High durability reduces repair frequency |

| Construction | Cement or aggregate distribution | Wear-resistant lining prevents abrasion |

| Agriculture | Grain and fertilizer handling | Precise positioning prevents spillage |

| Ports & Warehouses | Bulk material loading | Sensor-based control minimizes accidents and downtime |

4. How Durability Reduces Maintenance Costs

Durability directly correlates with lower maintenance:

-

High-strength materials → Fewer replacements

-

Intelligent hydraulic control → Reduced stress on cylinders and valves

-

Accurate positioning and automation → Minimized accidental collisions

-

Wear-resistant coatings → Extended service life in abrasive environments

-

Safety sensors → Prevent costly emergency repairs

| Feature | Benefit | Cost Reduction |

|---|---|---|

| Q690/NM400 body | Long lifespan | Reduced material and labor costs |

| Multi-stage cylinder | Smooth motion | Less wear, fewer replacements |

| PLC + sensors | Accurate operation | Prevents collisions and misalignment |

| Modular components | Easy maintenance | Reduced downtime |

| Overload protection | System safety | Avoids expensive repairs |

5. Case Study: Reducing Maintenance in a Coal Plant

-

Challenge: Frequent hydraulic failures and chute wear caused operational delays.

-

Solution: Implemented Huoheshi telescopic chutes with high-strength lining and intelligent hydraulic drive.

-

Results:

-

Maintenance downtime reduced by 40%

-

Component replacement costs decreased by 35%

-

Loading efficiency increased by 25%

6. Maintenance Best Practices

To maximize chute lifespan:

-

Regular inspections of hydraulic hoses, sensors, and cylinder seals.

-

Lubrication of moving parts to reduce friction.

-

Sensor calibration to ensure precise positioning.

-

Load management to avoid overloading.

-

Environmental protection to minimize dust, moisture, and corrosion.

7. Advantages Over Conventional Chute Systems

| Aspect | Conventional | Huoheshi Telescopic Chute |

|---|---|---|

| Material | Standard steel | Q690 + NM400 wear-resistant |

| Hydraulic system | Basic | Intelligent, load-sensing, energy-efficient |

| Safety | Limited | Overload, collision sensors, emergency manual pump |

| Accuracy | Low | Millimeter-level precision |

| Maintenance | Frequent | Reduced downtime & extended service life |

8. Future Trends and Innovation

-

IoT-enabled monitoring: Predictive maintenance through real-time sensor data.

-

Energy optimization: Advanced hydraulic pumps reduce energy consumption.

-

Modular upgrades: Quick replacement modules minimize downtime.

-

Automation integration: AI-assisted logistics and autonomous vehicle loading.

9. FAQ

Q1: What makes Huoheshi’s chutes durable?

A: High-strength steel, wear-resistant linings, and modular design.

Q2: How does intelligent hydraulic drive reduce costs?

A: Smooth operation reduces component wear and prevents hydraulic stress.

Q3: Can it adapt to different vehicles?

A: Yes, chutes flexibly handle trucks, trains, and hoppers.

Q4: What safety mechanisms are included?

A: Overload protection, collision sensors, and manual emergency pump.

Q5: How does automation help?

A: Reduces human error, improves precision, and extends equipment lifespan.

10. Conclusion

Durable telescopic chute hydraulic systems are a strategic investment for industries handling bulk materials. Huoheshi Hydraulic combines:

-

High-strength, wear-resistant materials

-

Intelligent hydraulic control

-

Precise positioning systems

-

Comprehensive safety mechanisms

These features ensure reduced maintenance costs, extended service life, improved efficiency, and enhanced safety, providing significant long-term operational savings.

www.huoheshi-hydro.com

Wuxi Huoheshi Hydraulic Technology Co., Ltd.