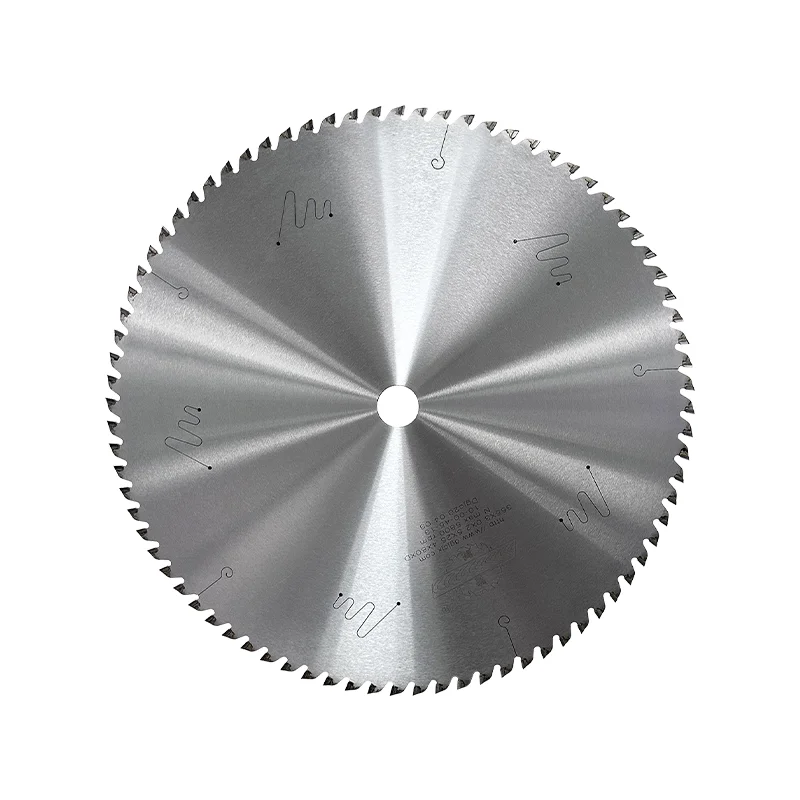

Wholesale tungsten carbide circular saw blades, choose professional manufacturers

5 min readIn the fields of metal processing, aluminum cutting, plastic cutting and other industrial production, tungsten carbide circular saw blades have become the first choice for many factories and processing companies due to their high hardness, high wear resistance, excellent cutting performance and wide applicability. For wholesale buyers, how to choose a professional tungsten carbide circular saw blade manufacturer is not only related to the quality of the product, but also directly affects the end-customer experience and the long-term cooperative relationship of the enterprise. This article will analyze in depth from multiple dimensions why it is so important to choose a professional manufacturer when wholesale tungsten carbide circular saw blades, and provide practical suggestions for enterprise buyers on factory selection.

1. Advantages of tungsten carbide circular saw blades: Why is it so popular?

Tungsten steel, also known as cemented carbide (Tungsten Carbide), is an alloy material made of high-hardness tungsten carbide powder and metal cobalt or nickel powder through a sintering process. After being used to manufacture circular saw blades, its performance far exceeds that of ordinary high-speed steel (HSS) or carbon steel materials. Its main advantages are as follows:

High hardness and long life

The hardness of tungsten steel is as high as HRA90 or above, which is several times that of ordinary steel. Using tungsten carbide circular saw blades can significantly improve cutting efficiency, reduce the frequency of blade replacement, and reduce corporate maintenance costs.

High cutting accuracy

Tungsten carbide circular saw blades have sharp teeth and neat blade edges, which can achieve high-precision cutting and are not prone to burrs, cracks, and other problems. They are particularly suitable for high-demand processing scenarios such as aluminum, copper, and PVC.

Strong wear resistance

It still maintains good sharpness after long-term high-speed cutting, effectively improving production continuity.

Wide applicability

It is suitable for cutting a variety of materials such as aluminum profiles, copper, steel, plastic, and wood. It is widely used in furniture manufacturing, aluminum alloy doors and windows, metal processing, automotive parts, and machinery manufacturing.

2. Reasons for choosing a professional tungsten carbide circular saw blade manufacturer

2.1 Independent research and development and production capacity guarantee

Professional manufacturers usually have a complete product design, research and development, processing, and testing system, and use advanced CNC equipment and sintering technology to ensure that each saw blade undergoes a strict process. For example, whether the tooth design is reasonable, whether the base material is of high quality, and whether high-precision grinding equipment is used for processing are all key factors in determining the performance of the saw blade.

2.2 Traceable materials and stable quality

Regular manufacturers use tungsten steel materials with traceable sources, and have a stable supply chain system and a complete quality management system. Compared with small workshop-style suppliers, their product consistency and long-term stability are more trustworthy.

2.3 Strong customizable service capabilities

Wholesale purchases often require saw blades of various specifications, numbers of teeth, and apertures. Professional manufacturers can provide OEM/ODM services, customize saw blades of different specifications and sizes according to customer cutting needs, and even provide personalized tooth shape design to meet the precision cutting requirements of different industrial scenarios.

2.4 Timely after-sales service and professional technical support

Professional manufacturers are often equipped with a team of technical engineers who can provide timely technical support and processing suggestions when customers encounter cutting problems, saw blades that wear too fast, and loud noises.

3. Wholesale process and precautions of tungsten carbide circular saw blades

3.1 Clear procurement requirements

The purchaser should first confirm the basic parameters of the required saw blades, including:

Outer diameter (such as 255mm, 305mm, 355mm)

Number of teeth (such as 60T, 80T, 100T, etc.)

Aperture (20mm, 25.4mm, 30mm, etc.)

Purpose (aluminum, wood, stainless steel, etc.)

Special requirements (such as silencer holes, shockproof grooves, coating treatment, etc.)

3.2 Sample confirmation

It is recommended to ask the manufacturer for samples for testing first to evaluate the actual use effect, including cutting speed, cut surface finish, saw blade durability, etc., to ensure that the risk of bulk purchases is minimized.

3.3 Signing orders and contracts

Bulk purchases should sign a purchase contract to clarify the terms such as delivery time, transportation method, payment method, after-sales responsibility, etc. to protect the rights and interests of both parties.

3.4 Logistics and delivery

Professional manufacturers usually support wholesale supporting services such as logistics dispatch, warehousing docking, and bulk transportation, so that buyers can solve distribution problems in one stop.

4. Advantages of choosing us: Be your trusted wholesale partner for tungsten carbide circular saw blades

As a professional tungsten carbide circular saw blade manufacturer, we always adhere to the principle of "quality-oriented, service-first", and are committed to providing global wholesalers, distributors and terminal factory customers with saw blade products with superior performance and stable quality.

Our core advantages:

More than 10 years of industry experience: Deeply cultivating the field of carbide saw blades, with independent brands and patented technologies.

CNC precision equipment: fully automatic laser cutting, tooth surface grinding, and tooth shape finishing integrated production line to ensure product consistency.

ISO quality certification system: 100% inspection of factory products, and rejection of defective products.

Sufficient inventory and fast delivery: standard specifications and models are available in stock for a long time, and large orders can be customized and delivered in as fast as 3 days.

Global delivery support: Support exports to Southeast Asia, Europe, the United States, the Middle East and other countries and regions, with rich export experience.

Technical support team: can provide one-to-one technical services such as saw blade selection, cutting process suggestions, and after-sales maintenance.

In today's highly competitive market environment, choosing a tungsten carbide circular saw blade with stable performance and reliable quality can not only improve the processing efficiency of the enterprise, but also bring a better user experience to downstream customers. At the wholesale procurement level, cooperating with a professional, powerful and well-serviced manufacturer is undoubtedly a key step towards long-term development and steady profitability.

If you are looking for a wholesale channel for high-quality tungsten carbide circular saw blades, please contact us to obtain the latest price list, product catalog and technical information. We will provide you with the most cost-effective wholesale solution!

www.chinechernmachine.com

DongGuan Chine Chern Machinery Co.,Ltd.