Comparing Brushless and Brushed Drone Electronic Speed Controllers

4 min readWhen it comes to building or upgrading drones, one of the most critical components that determine performance, efficiency, and reliability is the Electronic Speed Controller (ESC). ESCs act as the intermediary between the flight controller and the motors, regulating power and controlling the speed, direction, and braking of each motor. For drone enthusiasts and professionals alike, choosing the right type of ESC is vital. Broadly, ESCs can be classified into two main categories: brushed ESCs and brushless ESCs. Understanding the differences between these two types is crucial for optimizing drone performance, flight time, and durability.

In this article, we will provide a comprehensive comparison of brushless and brushed drone electronic speed controllers, examining their structure, working principles, advantages, disadvantages, and ideal use cases.

What is a Brushed Drone Electronic Speed Controller?

A brushed ESC is designed to control brushed DC motors, which are one of the oldest types of motors used in drones and other RC vehicles. Brushed motors use mechanical brushes to transfer electrical current to the motor’s rotating armature. This simple mechanism allows the motor to spin when powered.

Brushed ESCs are relatively straightforward. They control motor speed by varying the voltage applied to the motor. Essentially, the ESC acts as a switch, turning the motor’s power on and off very quickly to regulate speed. This simplicity makes brushed ESCs lightweight, inexpensive, and easy to repair.

Key Features of Brushed ESCs

-

Simplicity: Brushed ESCs have fewer components, making them easy to operate and maintain.

-

Lower cost: Ideal for beginners or budget-friendly drones.

-

Compact size: Works well with small drones where weight is a major concern.

-

Direct control: Voltage modulation allows for precise low-speed control.

Limitations of Brushed ESCs

-

Lower efficiency: Mechanical friction from brushes causes energy loss and heat generation.

-

Shorter lifespan: Brushes wear out over time and require replacement.

-

Limited power handling: Not suitable for high-speed, high-power racing drones.

-

Maintenance: Brushes and commutators need regular inspection.

Brushed ESCs are commonly found in toy drones, micro drones, and low-cost quadcopters, where flight times are short, and efficiency is less critical.

What is a Brushless Drone Electronic Speed Controller?

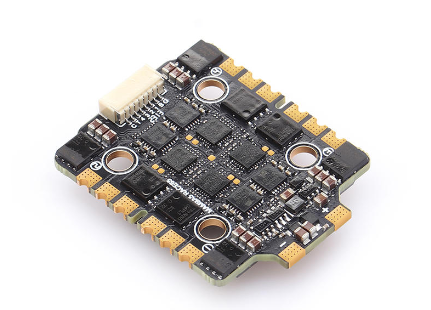

In contrast, a brushless ESC is designed for brushless DC motors (BLDC motors), which are now standard in most modern drones. Unlike brushed motors, brushless motors do not use mechanical brushes; instead, they rely on electronic commutation to switch current in the motor windings. This design eliminates friction and wear, allowing brushless motors to operate more efficiently and last longer.

A brushless ESC is more complex than a brushed ESC. It must calculate rotor position and continuously switch the current in the stator windings to maintain smooth rotation. This process requires more sophisticated electronics and firmware, often including features like active braking, throttle response optimization, and programmable settings.

Key Features of Brushless ESCs

-

Higher efficiency: No brushes reduce friction and energy loss, extending flight time.

-

Long lifespan: Fewer moving parts mean less wear and tear.

-

High power handling: Capable of supporting high-speed, high-performance drones.

-

Advanced features: Programmable ESCs allow for motor timing adjustments, braking control, and throttle curve customization.

-

Better cooling: Most brushless ESCs include heat dissipation features to maintain performance.

Limitations of Brushless ESCs

-

Higher cost: More complex electronics and firmware make brushless ESCs more expensive.

-

Increased weight and size: Slightly heavier than brushed ESCs, which may affect very small drones.

-

Complexity: Requires correct configuration and firmware updates for optimal performance.

-

Installation: Can be more challenging for beginners.

Brushless ESCs are the standard choice for professional drones, racing drones, and long-endurance UAVs, where efficiency, performance, and reliability are priorities.

Performance Comparison: Brushed vs. Brushless ESCs

| Feature | Brushed ESC | Brushless ESC |

|---|---|---|

| Motor type | Brushed DC motors | Brushless DC motors |

| Efficiency | Lower, due to brush friction | Higher, minimal energy loss |

| Lifespan | Shorter, brushes wear out | Longer, minimal mechanical wear |

| Maintenance | Regular brush replacement required | Minimal maintenance |

| Cost | Low | Higher |

| Power handling | Low to moderate | High |

| Control precision | Moderate | High, supports programmable features |

| Heat generation | Higher | Lower |

| Flight applications | Toys, beginner drones | Racing, commercial, professional drones |

From the comparison above, it’s clear that brushless ESCs outperform brushed ESCs in almost every technical aspect, except for cost and simplicity.

Use Cases: Choosing the Right ESC for Your Drone

When to Choose a Brushed ESC

-

You are building entry-level drones or micro quadcopters.

-

Budget is a major concern.

-

Your drone has lightweight motors and short flight times.

-

You prefer ease of replacement and maintenance.

When to Choose a Brushless ESC

-

You are building high-performance racing drones or professional UAVs.

-

Efficiency and longer flight time are critical.

-

You want high-speed precision control for aerobatics or payload operations.

-

You require low maintenance and high reliability for long-term usage.

Advances in Brushless ESC Technology

Modern brushless ESCs continue to evolve, offering features that were previously unimaginable:

-

BLHeli and KISS Firmware: Advanced ESC firmware that allows customizable throttle curves, active braking, and smoother motor response.

-

DShot Protocol: Digital communication between ESC and flight controller for higher accuracy and no signal interference.

-

Integrated Telemetry: Real-time monitoring of current, voltage, and temperature to prevent damage.

-

Waterproofing and Cooling: ESCs designed for outdoor or harsh environments with effective heat dissipation systems.

These innovations make brushless ESCs highly adaptable for commercial drones, FPV racing, and industrial UAVs.

Conclusion

Choosing between brushed and brushless drone electronic speed controllers depends largely on your drone’s intended use, budget, and performance expectations. While brushed ESCs are cost-effective, simple, and suitable for hobbyist drones, brushless ESCs provide unmatched efficiency, longevity, and control precision, making them the ideal choice for professional and high-performance drones.

Understanding the differences between these ESC types ensures that drone builders can maximize performance, flight time, and reliability, while also making informed decisions about maintenance and long-term costs.

For anyone serious about drone technology, investing in a high-quality brushless ESC is a decision that pays off in smoother flights, extended motor life, and overall better drone performance.

www.pega-fly.com

pega-fly